The Benefits of Slab on Grade

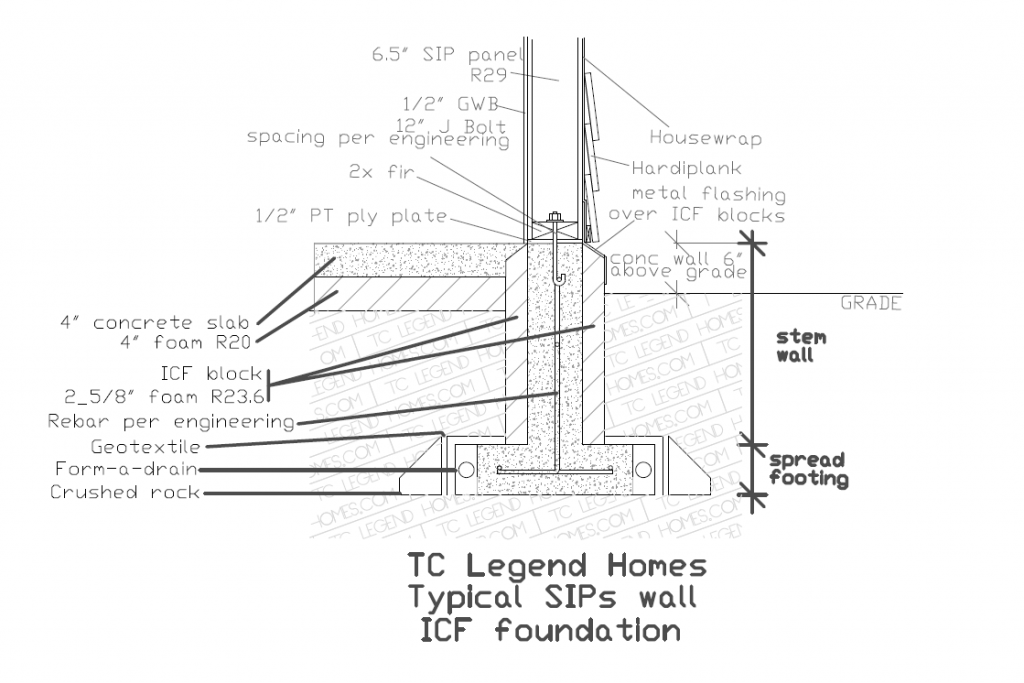

When we pour a slab on grade we are basically pouring concrete directly onto the earth. Sure, there is a 4” layer of foam under the concrete so we don’t lose our heat, and yes, there is 12” of sand under the foam so the foam sits perfectly flat and the plumber can easily locate drainpipes in the sand… but under that sand is the compacted native earth.

No crawl space, rats, trash or mold, just a crisp concrete slab sitting on the earth, insulated so the slab holds in heat (or cold), and keeps the temperature inside the house consistently stable.

Slab-day is stressful, because many of the affordable Net-Zero houses from TC Legend use the slab-on-grade as the finished-floor.

Concrete slab as a finished floor provides a cost-effective, durable, aesthetically modern floor. However, the concrete needs to be finished perfectly flat on “Slab Day.”

Last week at the Lake Stevens house, the second concrete truck was late and the guys had to scramble to pour and screed the last truck-load before a permanent seam became inevitable!

Disaster was fortunately averted, the 1,500 square foot (sf) floor had the seam massaged-out, was troweled flat, covered in plastic and will be scrubbed and sealed in a few months before the trim goes up.

There are other finish options for concrete floors; they can be ground down, acid etched, and stain can be added to the concrete in the yard.

The following photos are gathered from a couple other already-built jobs. Dan was too busy at Lake Stevens last week, shoveling, troweling and de-stressing the crew to run a camera.

The black slab under the mountain was poured using black dye within the concrete.

The yellow Legos are a layout grid for in-floor radiant hydronic heating, which until recently was one common heating option deployed within our Net-Zero homes (more on heating systems soon).

.

Recent Comments